CHOOSING A TELEHANDLER

Telehandlers are a critical tool for many situations where relocating materials safely and efficiently via forklift is necessary. There are many choices when considering which telehandler would be best suited for each specific application. Currently, there are two types of telehandlers available in today’s market.

PICK & PLACE

OR

PICK & CARRY

IT IS IMPORTANT TO NOTE THAT MACHINES WITH MORE BOOM SECTIONS AND/OR ARE EQUIPPED WITH OUTRIGGERS HAVE AN INCREASED OPERATING WEIGHT, WHICH REDUCES GRADEABILITY.

Xtreme XR Telehandler Pick & Carry (Non Outrigger) Models

Xtreme Manufacturing’s unique offering allows Pick & Carry models (listed below) to be transformed to Pick & Place machines.

Our patented chassis design includes a removable bolt for easy installation of a bolt-on outrigger kit.

*Load Chart & Model Number Changes with the Addition of Outriggers

Please call 1-800-497-1704 to consult with our Xtreme XR Telehandler factory sales team for any questions or concerns.

SAFETY CONSIDERATIONS

Safety is always the primary consideration when choosing which telehandler to utilize to complete your task. Variables that could impact your application decision include but are not limited to the following:

What is the stability and overall condition of the jobsite terrain?

Is additional stability required to relocate the load?

What is the stability of the area where the load will be landed?

What is the weight of the load being moved?

What load center is required?

How much reach is required to relocate the load?

How much height is required to relocate the load?

What is the distance requirement to transport the load?

What forklift attachments could be required to complete the task?

How constricted is the jobsite environment to navigate?

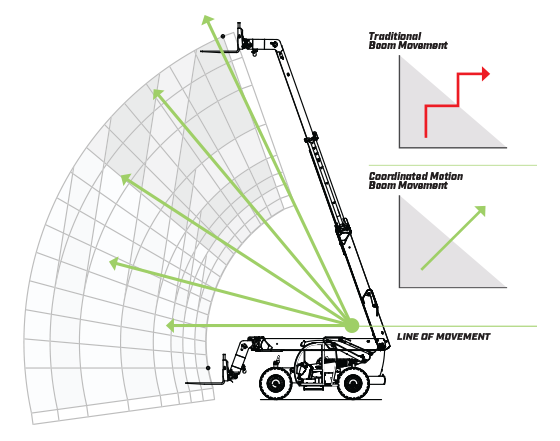

COORDINATED MOTION

TAKE CONTROL WITH THE NEW COORDINATED BOOM CONTROL OPTION FROM XTREME MANUFACTURING.

Designed to enhance operator control of the load, particularly when working on uneven terrain, this new option will be available on select models.

This option includes two new sensors on the boom, which enable new horizontal and vertical boom operation modes. The new length and angle sensors allow operators to achieve true horizontal and perpendicular fork motions, independent from the angle of the chassis.

Ideal for the masonry industry, this option gives much greater control of the load position, making it safer, easier and smoother to pick and place loads at height.